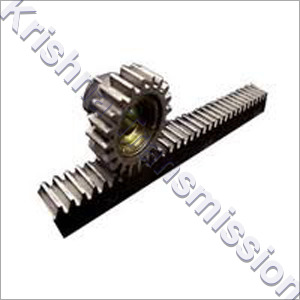

Spiral bevel gear

Product Details:

- Product Type Spiral bevel gear

- Color OHER

- Usage INDUSTRIAL

- Material Stainless Steel

- Processing Type Forging

- Gear Tooth Profile Other

- Click to View more

Spiral bevel gear Price And Quantity

- 1000 INR/Piece

- 2 Piece

Spiral bevel gear Product Specifications

- Other

- OHER

- Spiral bevel gear

- Stainless Steel

- INDUSTRIAL

- Forging

Spiral bevel gear Trade Information

- Paypal Cash Advance (CA) Cash in Advance (CID)

- 100 Piece Per Week

- 2 Days

- All India

Product Description

Capacity:- O.D. - 2" to 48" 1 module to 20 module or 32 D.P. to 1 D.P.

- Face width 1" to 10"

The Spiral Bevel Gear is a precision-engineered component designed to transfer power between shafts that intersect at an angle, usually 90 degrees. It features helical teeth that are cut along a conical surface, which allows for smooth, gradual engagement and minimizes noise and vibration during operation. This gear type is typically manufactured from high-strength materials such as alloy steel or stainless steel to ensure exceptional durability and performance under heavy loads and high speeds.

Key Features

- Helical Teeth Design The spiral tooth configuration provides smooth, quiet, and efficient power transmission with reduced noise and vibration compared to straight bevel gears.

- High Strength Constructed from robust materials like alloy steel or stainless steel, offering excellent load-carrying capacity and resistance to wear.

- Precision Engineering Designed to deliver accurate and reliable performance, enhancing the efficiency and longevity of mechanical systems.

- Versatile Applications Commonly used in automotive differentials, industrial machinery, and aerospace systems where reliable power transmission at right angles is required.

Applications

Spiral bevel gears are ideal for use in high-performance applications where noise reduction and smooth operation are crucial. They are widely utilized in automotive drive systems, industrial gearboxes, and aerospace equipment, making them essential for applications demanding precise and efficient angular power transmission.